Finished

product with seed.

So, spurred on by the heady rush of

less-than-complete-failure from previous

woodworking projects, I decided once again that I had too much

money/blood/self esteem, and set out on a new woody endeavor. Like

every time before, I started out with a simple idea. We have birds.

We have bird food. We do not have an effective means to transmit the

food to the birds.

Please

sir, may I have some more?

The simple solution would be to build

one of the time-honored old-timey bird feeders. The sort everyone

made in cub scouts or shop class. It was good enough for my pappy,

and damn it, it's good enough for me. Except for the part where it's

not.

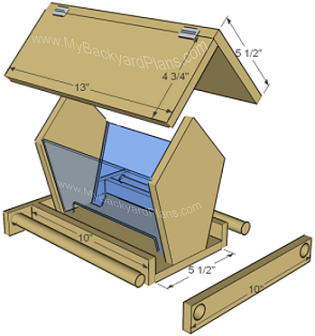

Every

boy scout from prehistory on made one of these. 99% of them

promptly fell apart the moment a bird landed on them.Photo courtesy of Mybackyardplans.com

Every time I start down the path of a

new wood project, you can almost pinpoint the moment where simple

gets chucked over for ludicrously complicated. It's the precise

moment when my brain sees something shiny and says “I can do

that!”. In this case, it was a plan from Lowes which, oddly enough,

involved buying a lot of expensive materials from Lowes. To be fair,

I was also lured in by their one minute, “how

easy is this?” video. That video is a damn dirty lie.

Easy

to make! ...for Bob Villa.

So I threw over the tried and true but

slightly boring bird feeder for the shiny, acrylic, trendy, super

sexy....bird feeder. I may need to get out of the garage more. But

now was no time to exercise judgment or perspective, there were power

tools to cackle maniacally over.

The Build

It started fairly easily. The base is

composed of cedar 1X2s. The only tricky bit here was getting them

exactly the same length on my less than stellar mitre saw, and

spacing them out at 1/16th inch. Building this little

lattice gave me a disproportionate feeling of accomplishment.

Basic

layout.

I'd never worked with cedar

before, which isn't saying much because all I've ever used is

pine/whitewood. I know a marvelous world of woods lies out there

waiting to be explored. However, it also comes with less than

marvelous prices. Cedar is actually pretty cheap. If you can live

with it not being finished on one side (left rough), then it's pretty

good stuff. Once I added the end pieces, I gave it a coat of

Thompson's Water Seal. Cedar is weather and rot resistant already,

but this brought out some darker color and gave it a little more

protection. Even this early in the process, I was fairly sure I did

not want to have to make this thing twice.

End

pieces added

Water

Seal brushed on

Finished

base

The next step was to build

the “spreader” which would sit under the bird seed and make sure

it distibuted to the openings in the feeder. This was the first of

many steps that gave me the sneaking suspicion Lowes engineered this

thing to use as much wood/as many parts as possible, since I'm pretty

sure gravity would have accomplished the same thing. But a plan's a

plani,

so I dutifully built and installed the spreader. I spent a lot of

time hand sanding and staining the wood. Any rational person would

have realized “hey, no one's actually going to see that wood...”.

I hope by now I have established that rationality has no place in my

woodworking processii.

Spreader

and other pieces cut and finished

Spreader

assembled and installed.

With the base done, it was

time to start on the sides. Again, I spent a lot of time picking out

the best looking pieces of wood I could find to create the sides.

And, again, it occurred to me later that these beautifully sanded and

finished pieces will be permanently obscured by the siding. I was so

busy picking out the perfect pieces, I inadvertently cut both sides

on the same angle (they need to be mirror opposites.) I cursed and

went to cut new side pieces....and promptly cut them at the wrong

angle again. Eventually I got the sides done, and nailed on the

“siding”.

So

pretty....so wrong.

Side

trim cut and stained

Trim

installed right over that pretty wood.

With the wood work done, it

was time to install the acrylic. I had never worked with acrylic

before, but it seems like it's pretty much a staple of bird feeder

technology, so I figured, how hard could it be? A large pile of

shattered and discarded acrylic pieces in the corner of my project

desk attests to that answer. You can't just MAKE acrylic into what

you want, you have to coax it...convince it that it's in its best

interests to be what you want it to be. It's temperamental stuff.

Finally, though, after signing over my paycheck to Lowes and

fantastically shattering the heck out of several pieces, I got the

inserts cut and installed them on the sides.

Cutting

side panes

Matching

panes to sides

Installed

side pane

It may have just been lack

of oxygen from cedar dust coated lungs, or blood loss from acrylic

shards, but at this point I was feeling fairly satisfied with

progress. Now came the moment when all the pieces got put together.

This is usually the moment in my projects where that previous feeling

disappates rapidly and the frantic sanding and recutting to fit

begins. Also, desperate desperate tears and please for deific

intervention.

Side

units get attached to the base

Acrylic

panels get attached to the front and back as windows using fancy

screws and the acrylic top is fitted.

Top

gets screwed into the middle supports of the side.

While

the corner posts are screwed into the base, the middle supports on

each side are just held between the siding and the acrylic panel,

letting it slide up and down so you can remove the roof. Clever in

concept, horrendously hard to get the fit right in execution.

½

inch pipe flange added to bottom so this could be mounted on a pipe.

And make Lowes more money.

Finally everything was

squared away, and the final product was a (mostly) functioning bird

feeder. All that's left is to mount it on a galvanized pole in the

yard and fill it with seed. Then just sit back and watch birds

actively ignore it. I am both worried and morbidly intrigued that the

birds may crash fatally into the transparent topiii.

I guess worse comes to worst, if it fails at feeding the small feeder

birds who crash into it, it can always be repurposed as a vulture

feeder...

Front

elevation

Side

View

Rear

elevation

NOTES

iExcept

when it's a recipe, which if you've read this blog before, you know

is really taken as more of a suggestion.

iiOr

foresight.

iiiThe

actual plan from Lowes involved sandwiching two incredibly expensive

pieces of Lexan toegther and then spray painting it black. First of

all, Lexan? The stuff they make bulletproof windows out of? Do we

really need our bird feeder to be safe from stray sniper fire? And

two sheets of it? And then you buy spray paint to paint that

beautifully clear Lexan black? I'm pretty sure it would be cheaper

to hire a guy to just stand there and hand feed birds.

2 comments:

I laughed and laughed and laughed reading this. Occasionally I think of embarking on a project involving tools, and then I think, "Remember that technology class in 8th grade, where we had to build an engine, and a screwdriver, and something else, but you never built a screwdriver, because you spent an entire semester building an engine that took all of your classmates about two weeks? Did you LIKE that class?" and then I don't want to use tools any more.

It's more fun when 1) you pick the project, 2) it's not graded. I remember having to make a basketball hoop in shop class. We didn't get a net, just the hoop. I didn't have any place to mount it at our house, and we didn't have blacktop to dribble on. So it just sat there in lumpy misshapen agony, shaming me each time I went out to the garage. Probably still there for all I know.

Post a Comment